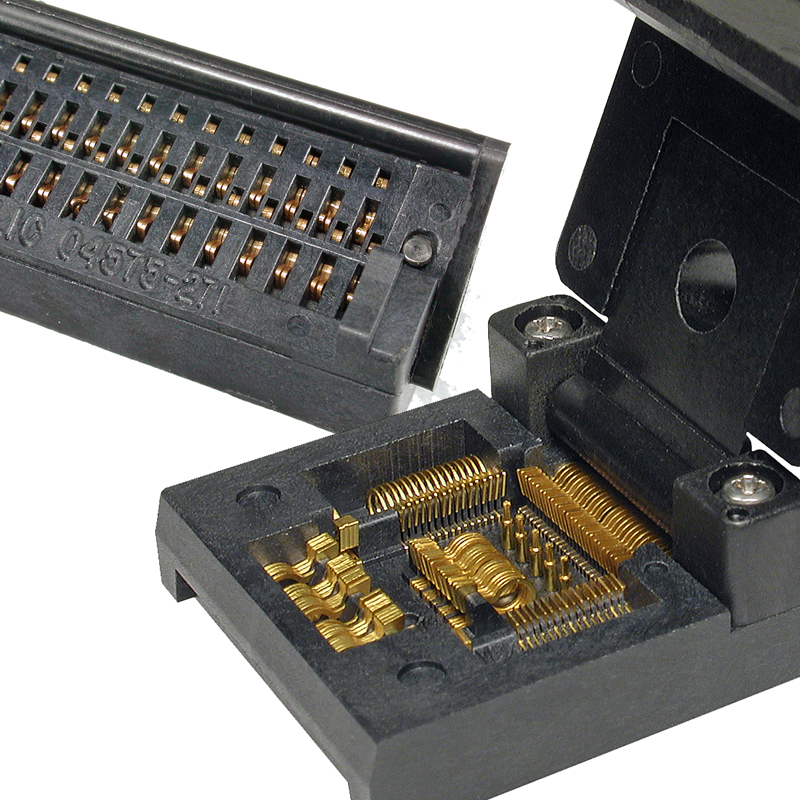

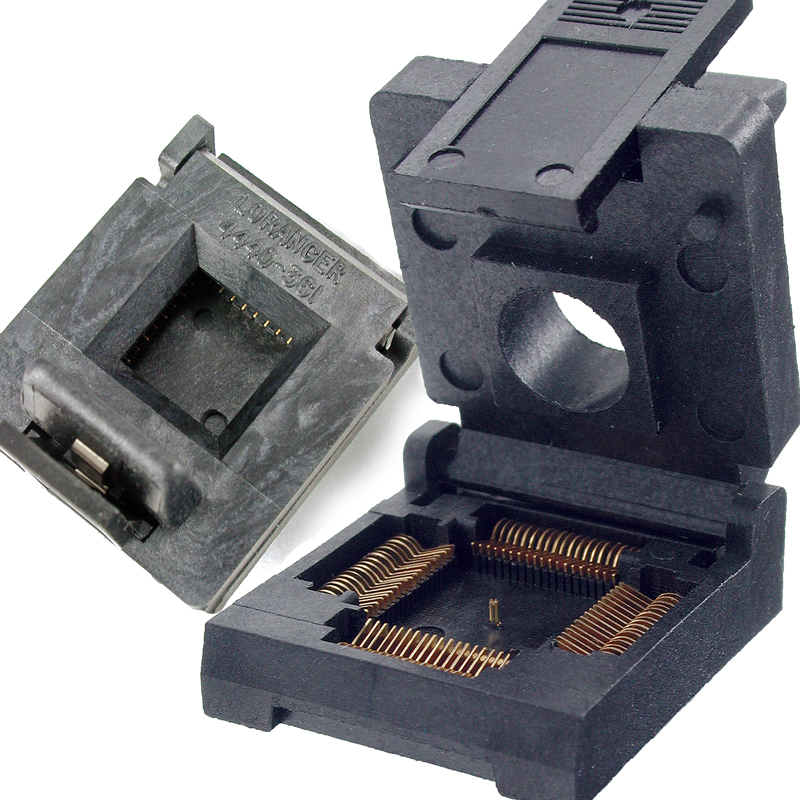

Loranger Sockets are designed to withstand the conditions of burn-in, test, HAST, humidity and repeated insertions. Below are some of the applications for Loranger sockets.

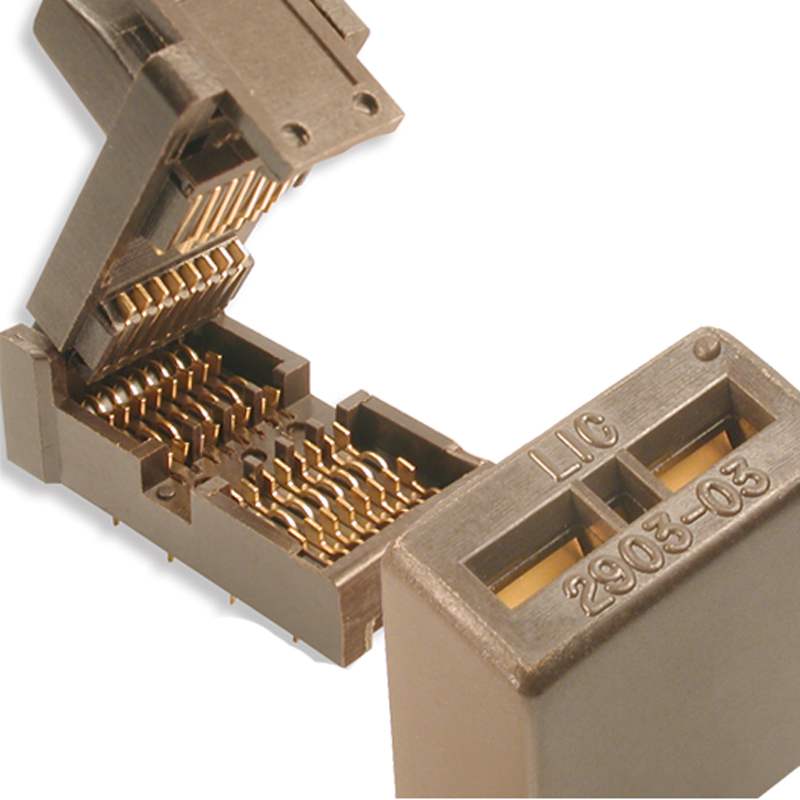

Loranger sockets are available in over 120 different standard and custom contact pitches. Typical pitches include 1.27 mm, 1.0 mm, 0.80 mm, 0.50 mm, 0.40 mm, 0.35 mm, 0.30 mm, 0.25 mm and smaller.

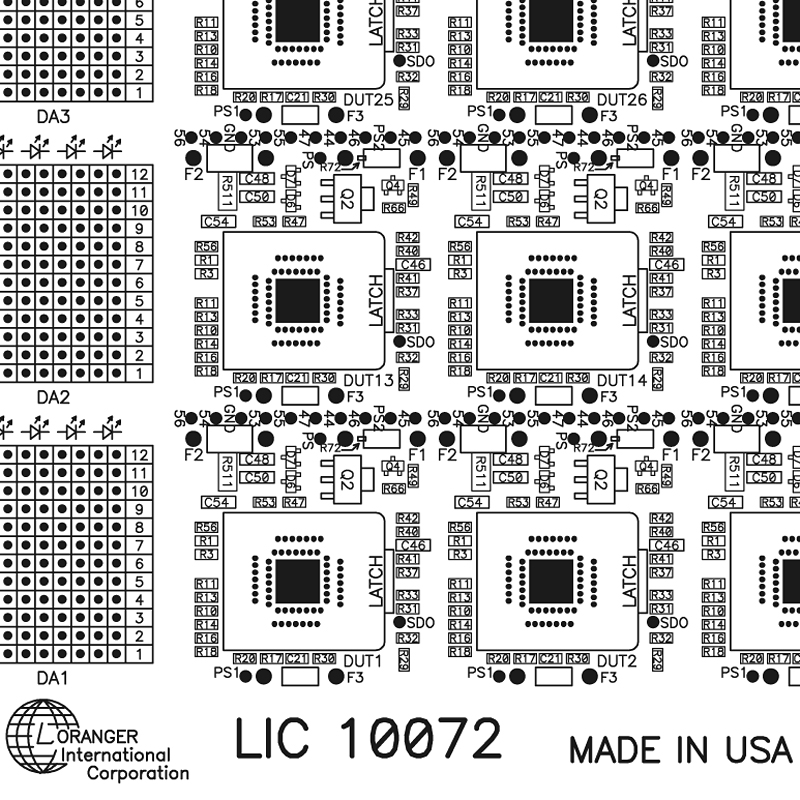

Loranger Burn-in and Test sockets are designed to have the smallest footprint possible. This allows an increased number of sockets on a burn-in board, and therefore increases the throughput of devices in each test run.

Loranger sockets are available with optional nonmagnetic materials for test and burn-in of devices that are affected by nearby magnetic materials.

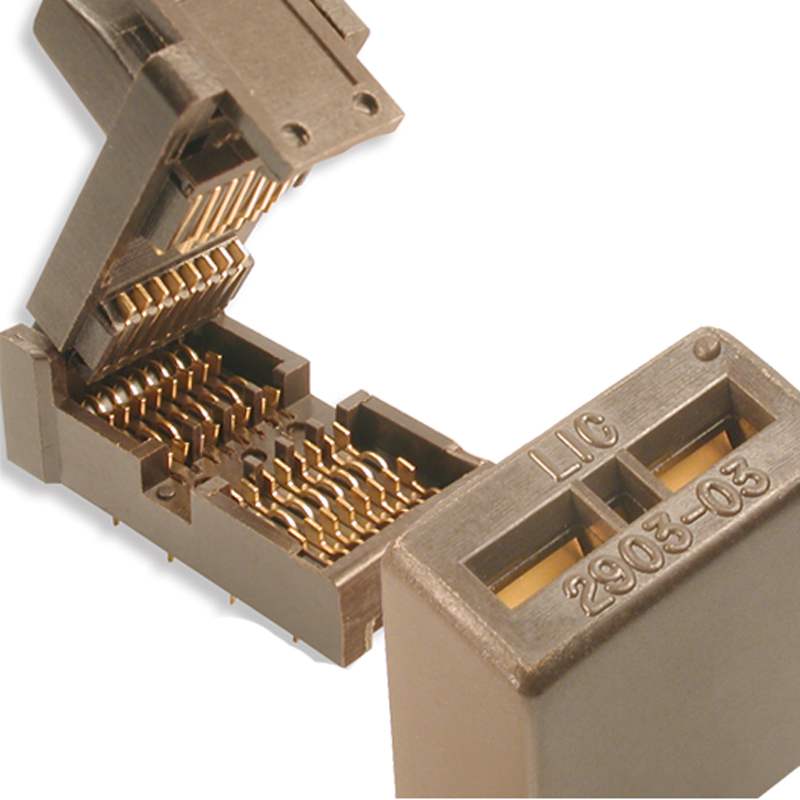

Hundreds of Loranger sockets are available with Kelvin connections. A Kelvin connection is two contact connections to one device pad or lead. When the device pad space is limited, Loranger also offers a “Double Duty Kelvin” contact. Why use Kelvin Contacts?

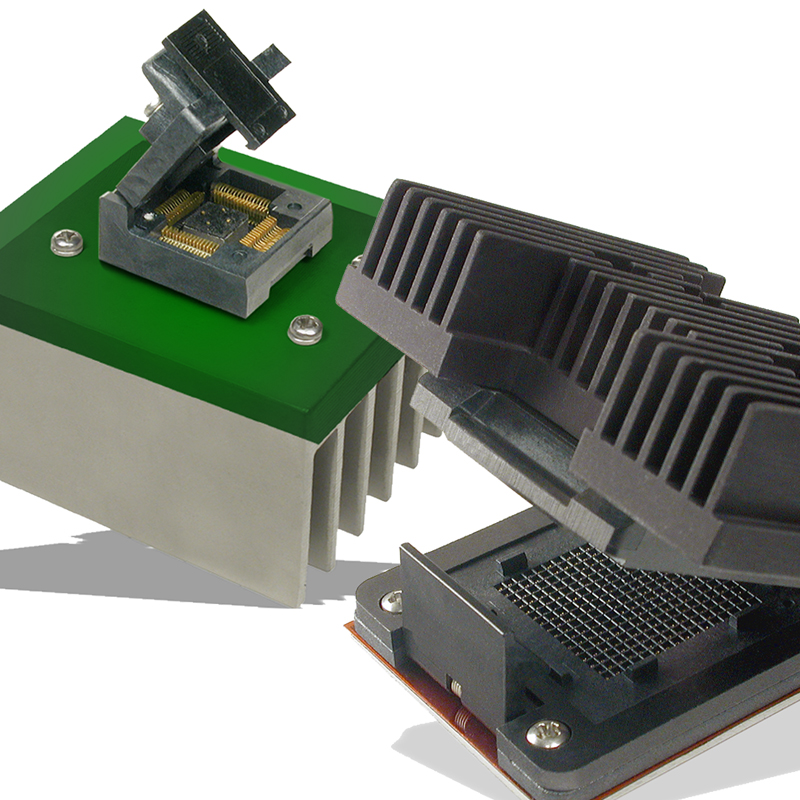

Loranger offers socket solutions to manage high wattage packages. Options are available for heatsinking, heating and temperature sensing. Programable heating is also available.

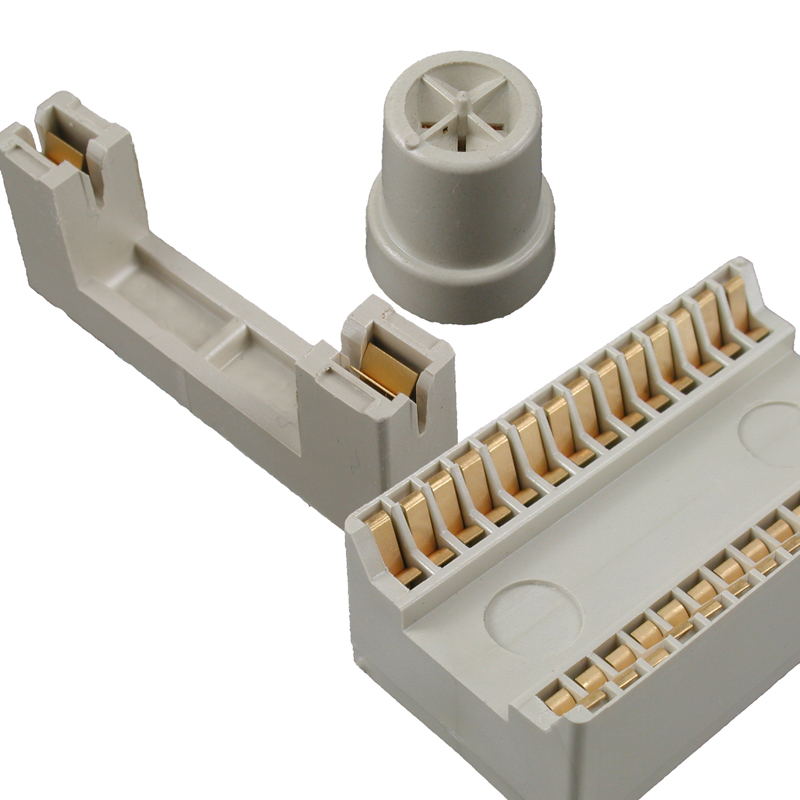

Loranger sockets can be used for test and burn-in of Crystal Oscillator packages, and are available with plated through hole or surface mount APS contacts. Socket are available for packages including: printed circuit card modules, LCC, DIP SIP, MEMS and QFN. Loranger sockets can also be used as an alternative to “Bed of Nails” test fixtures.

Loranger can add multiple socket contacts to device pads as space allows to accommodate high currents.

Standard Loranger sockets are available for up to 140 C or 175 C use. Optional socket materials are available for up to 210 C use, and for up to 300 C use.

Loranger sockets can be used for 85C / 85% humidity, and 130 C / 85% humidity (HAST) conditions. Loranger also designs and manufactures printed circuit boards and environmental systems for these conditions.

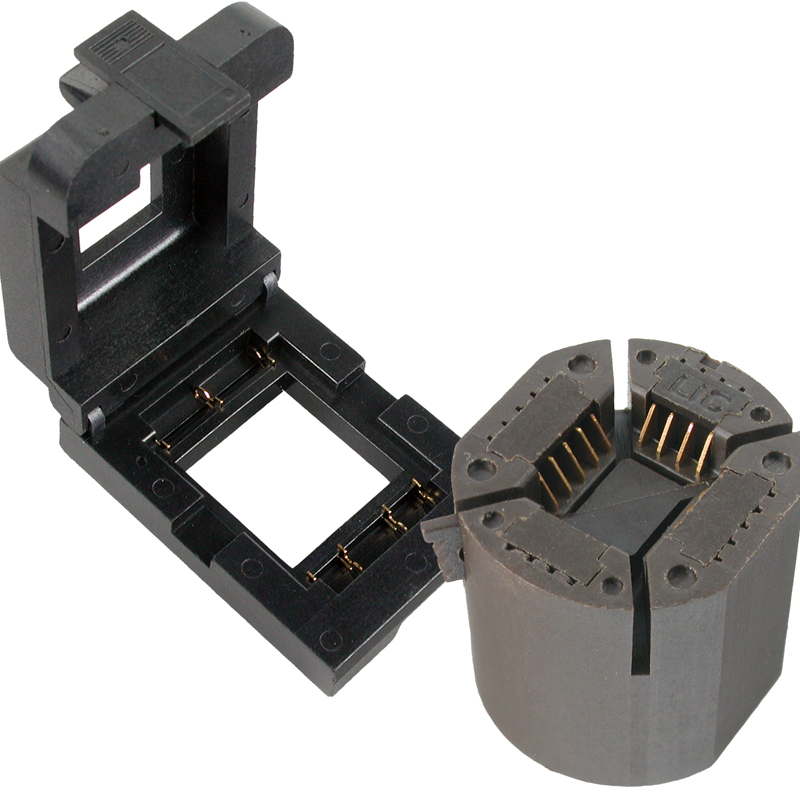

Loranger offers socket solutions to accommodate your optical and standard packages that require access to the top of the package. Test and Burn-in Sockets can be designed to accommodate digital camera imaging sensors, LEDs, and other optical package styles.

Loranger test and burn-in sockets are available for MEMS (microelectro- mechanical systems) devices. Sockets are available with nonmagnetic materials and fine pitch contacts, and can accommodate QFN, LCC, Gull Wing or other package styles

Loranger sockets can be used in Radiation Hardening test applications. Loranger has sockets for the standard TO, SMD and other package styles.